Professional Print Finishing Solutions

Eliminate fiber cracking, reduce waste, and handle jobs you couldn't touch before.

Find Your Machine

Get solutions engineered for your exact equipment

The Complete TechniCrease Guide

Learn everything about TechniCrease technology, applications, and proven results

Compatible With Leading Machinery Brands

Product Catalog

Precision-engineered systems for professional print finishing

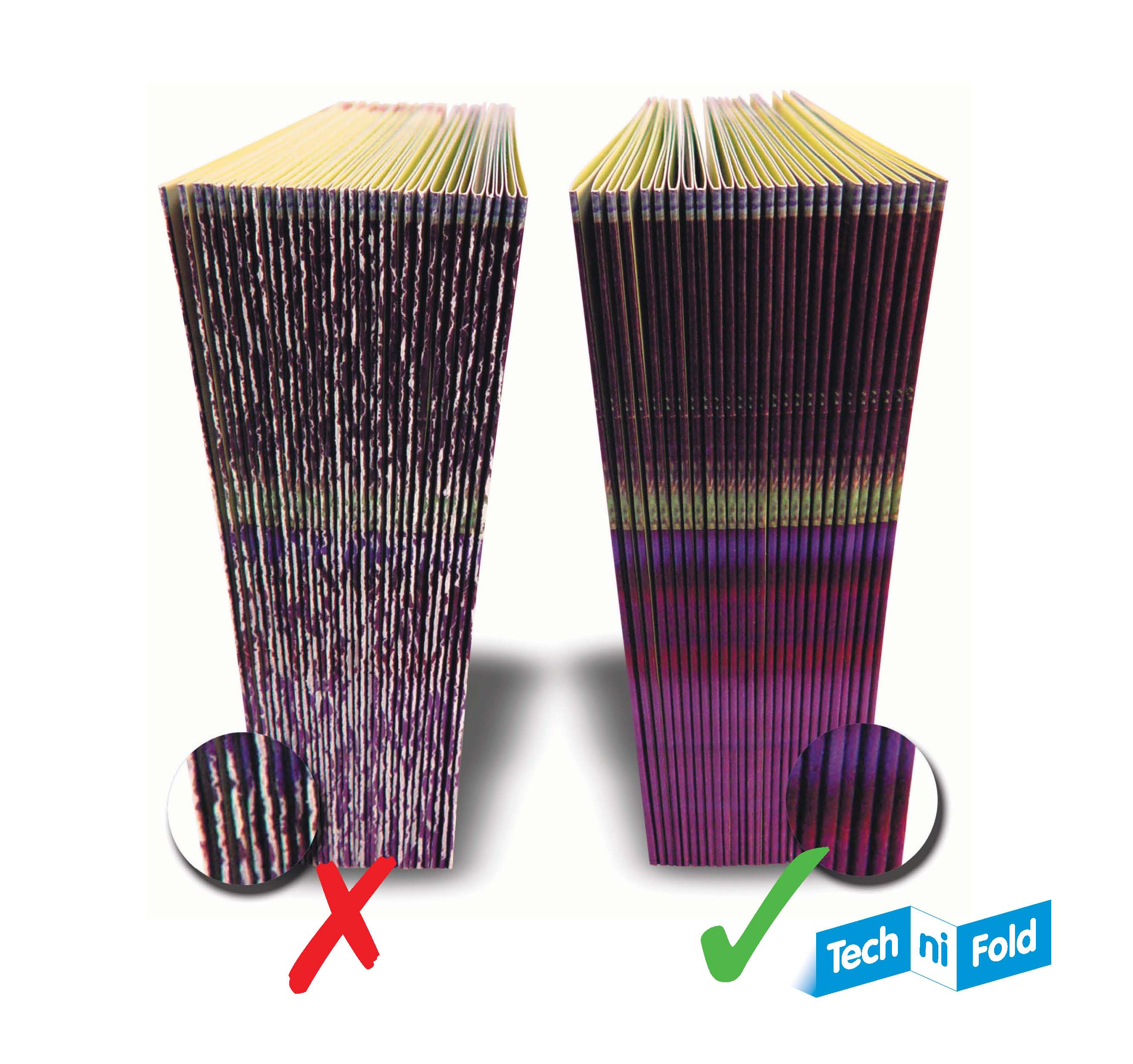

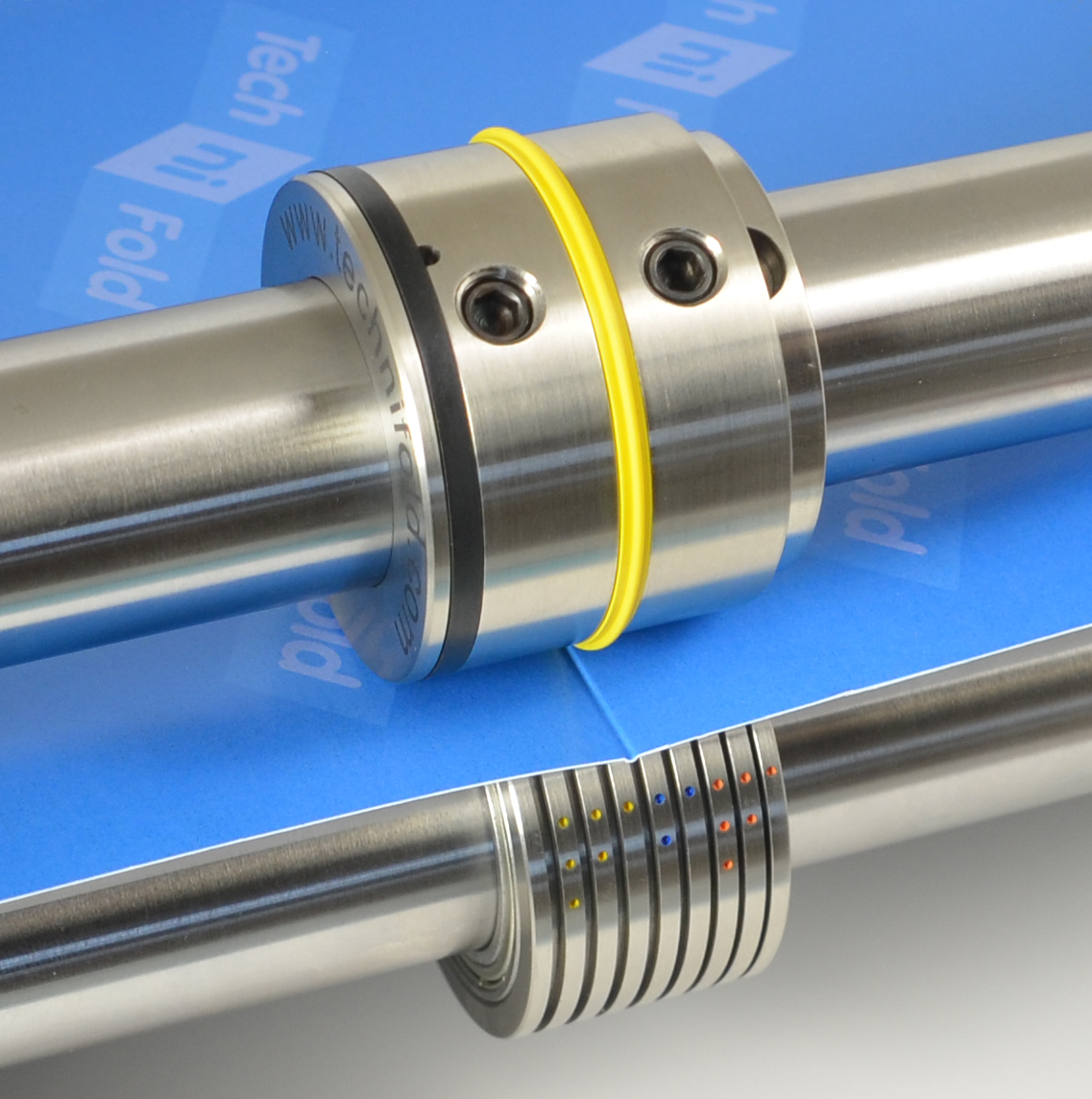

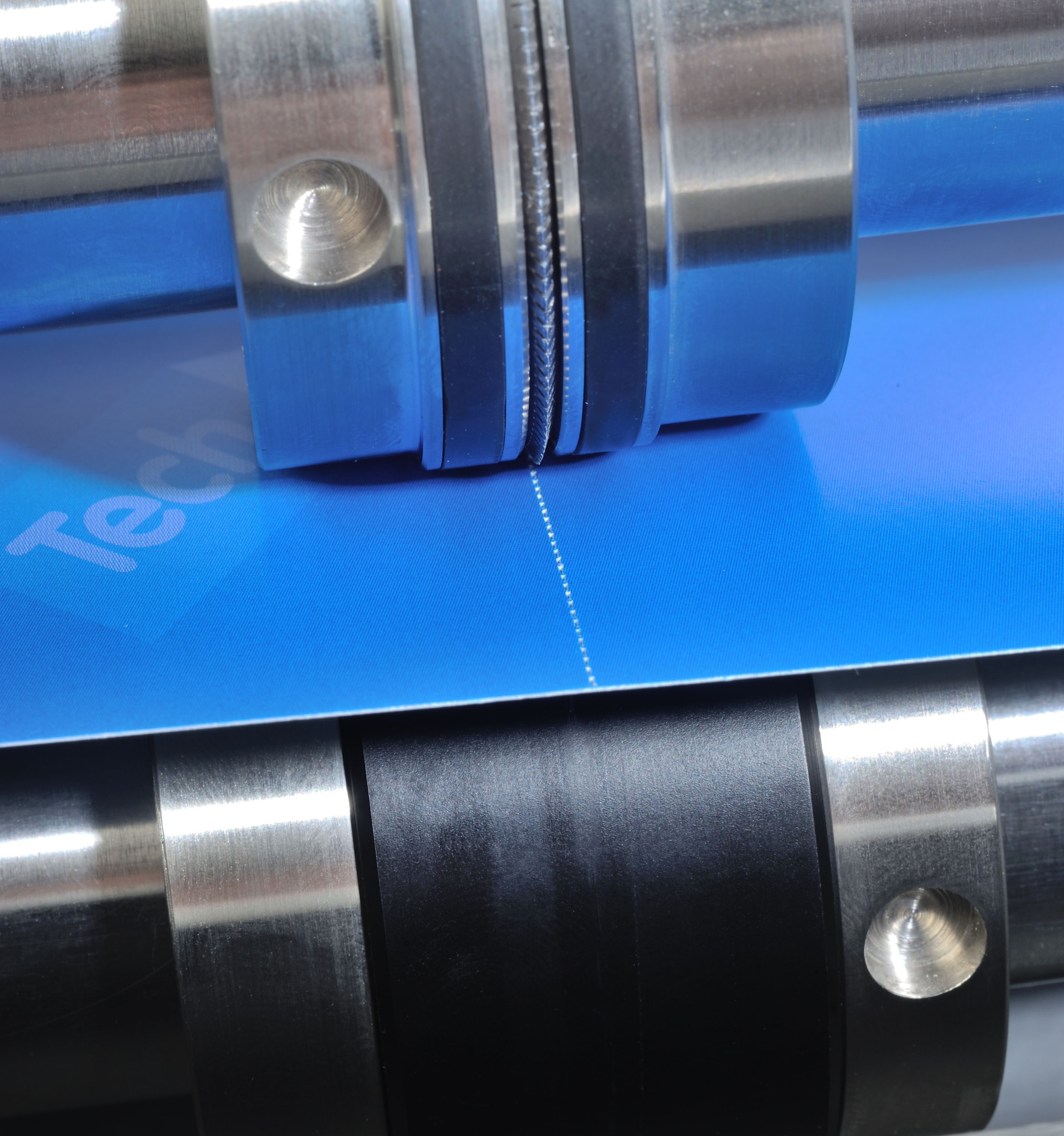

Tri-Creaser

The world standard for rotary creasing. Patented reverse-crease method eliminates fiber cracking on digital stocks, laminated sheets, and heavy substrates.

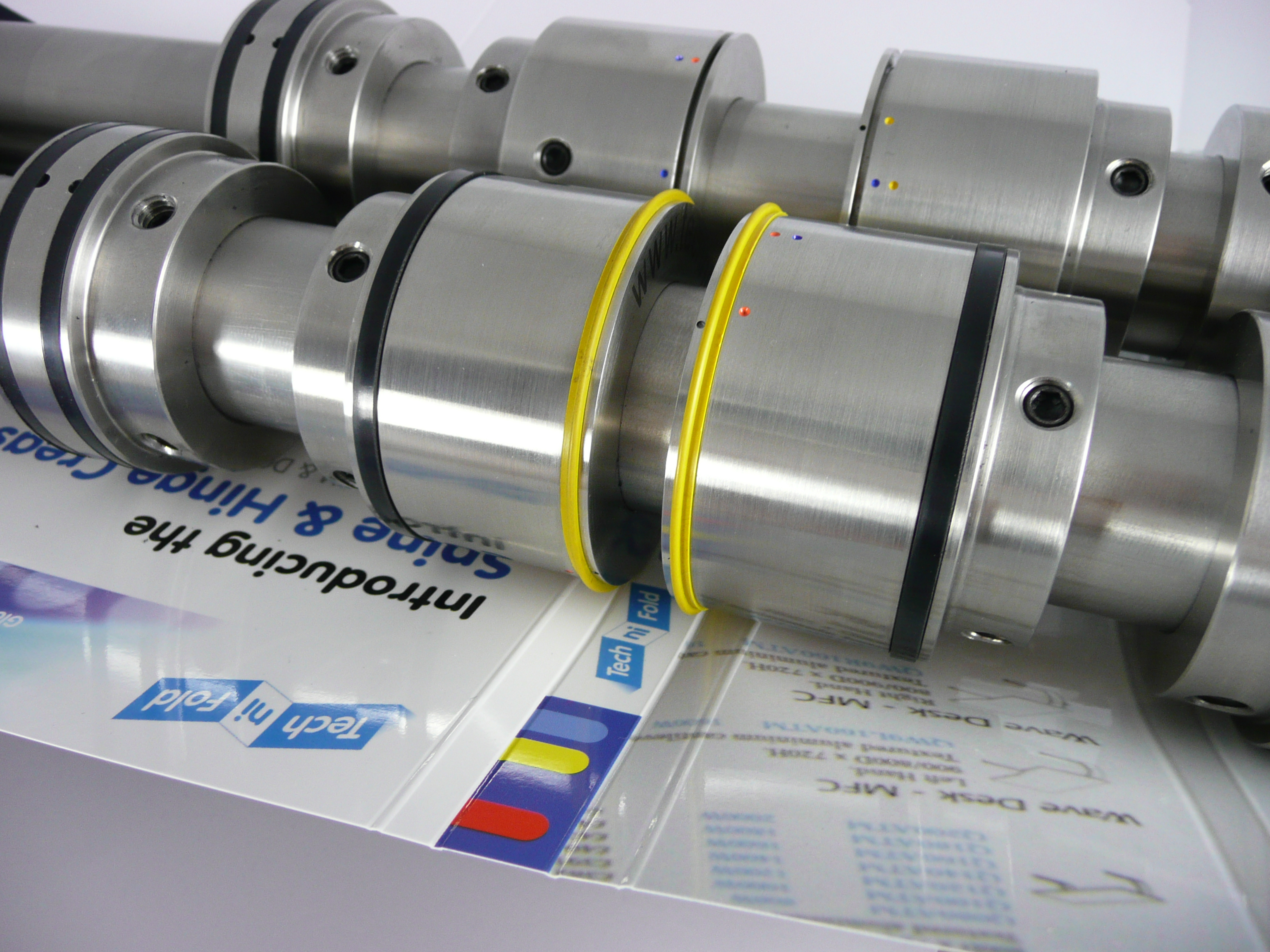

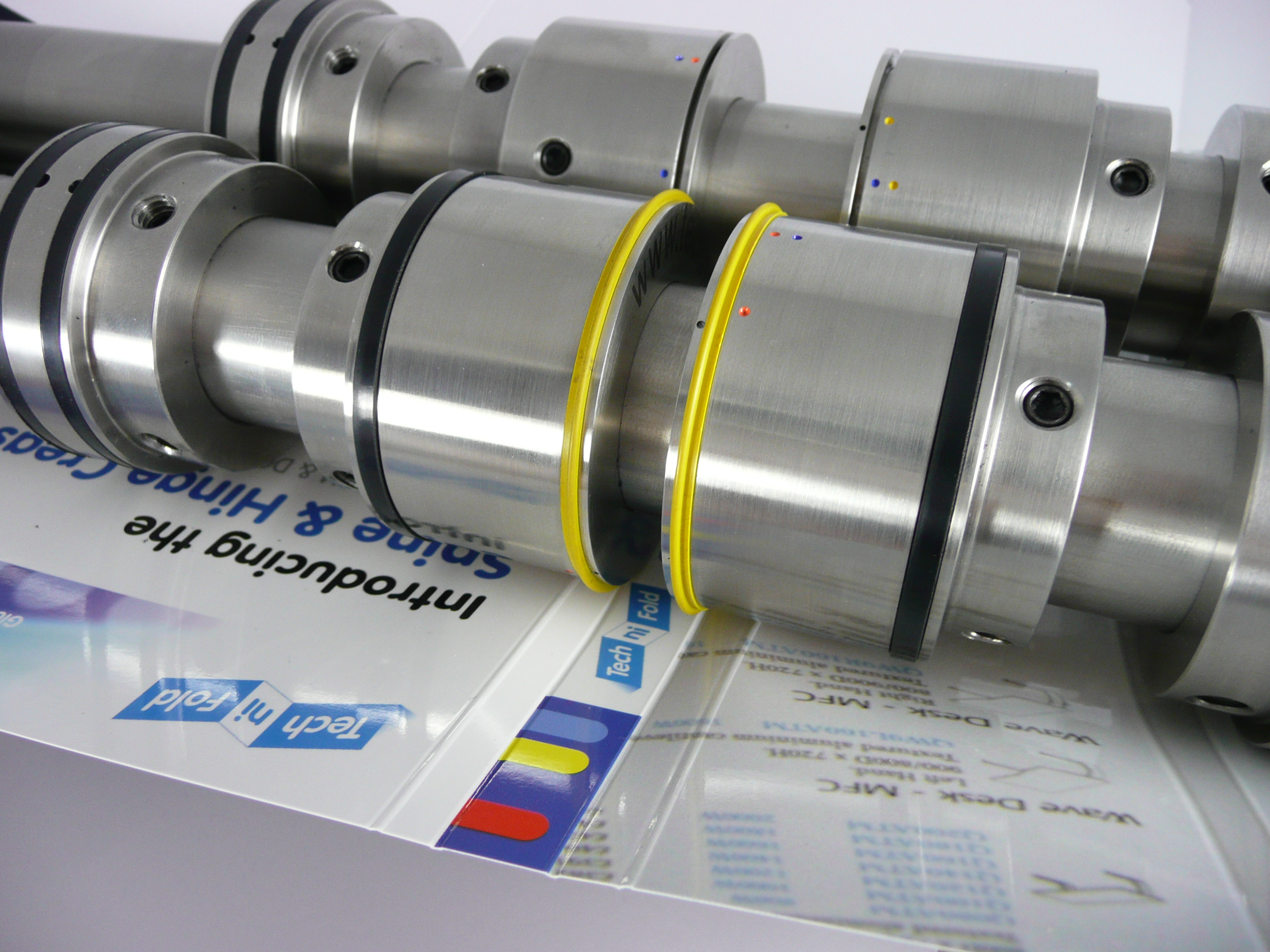

Quad-Creaser

Four independent creasing ribs for complex folding applications. Perfect parallel creases for greeting cards, invitations, and multi-panel work.

Spine Creaser

Pre-crease covers before perfect binding. Eliminates spine cracking on thick covers and achieves professional booklet finishing.

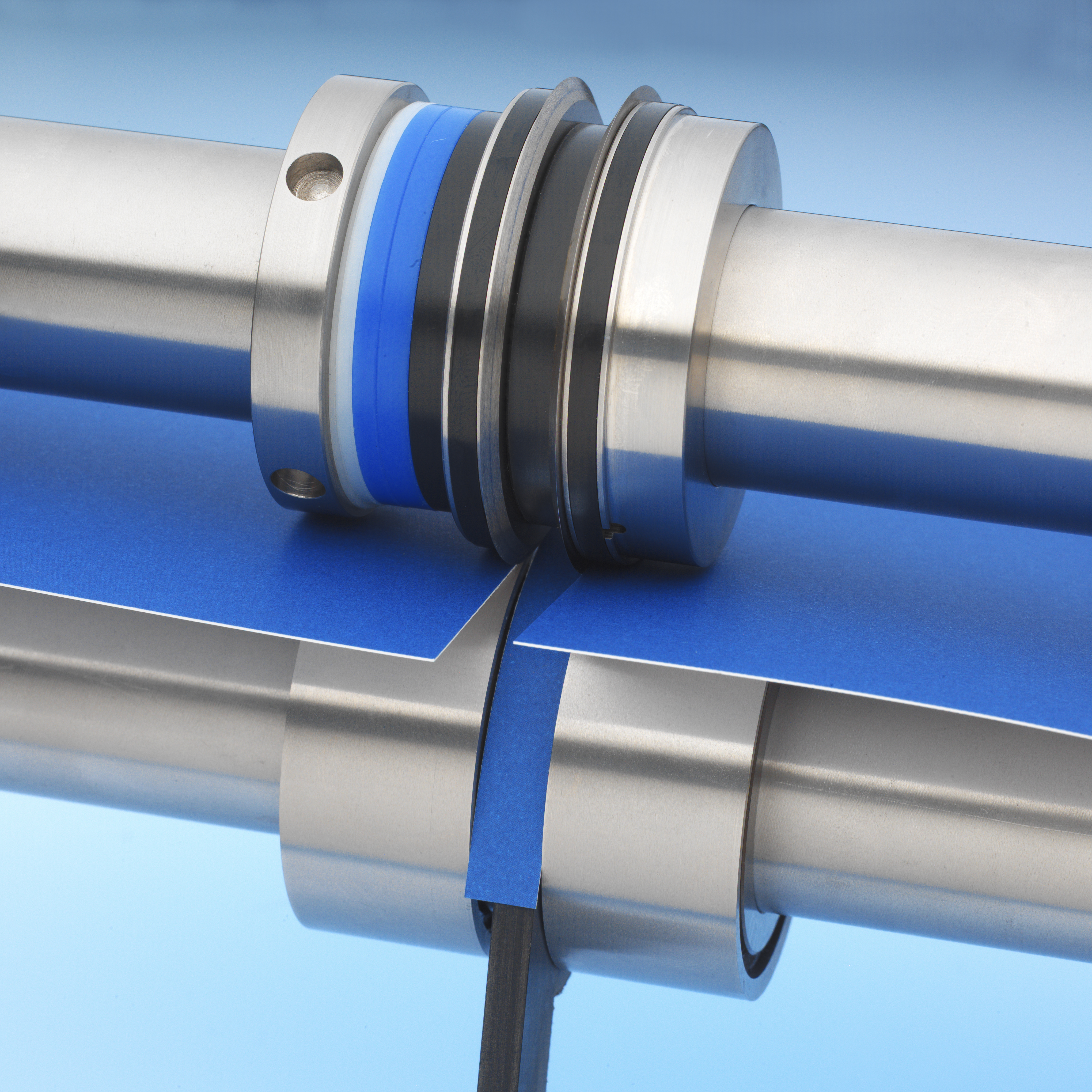

Spine & Hinge Creaser

Dual-crease system creates spine and hinge creases for 180° lay-flat opening. Essential for premium catalogs and manuals.

Multi-Tool

Versatile solution for irregular stocks, thick substrates, and specialty applications that standard folders cannot handle.

Micro-Perforator

Add clean tear-off sections to any folded product. Professional perforations for tickets, coupons, and reply cards.

Typical First-Year ROI

Based on average print shop operations

"Comparable to Letterpress Quality"

Sappi Paper Engineering conducted independent laboratory testing of Tri-Creaser technology against traditional scoring methods.

Request Your Free Trial

See the transformation yourself. Zero commitment. Most companies keep the full system.