Gripper Boss

Re-Grip Your Wheels in Seconds, Not Days

Fed up with sending gripper wheels away for expensive re-gripping? Gripper Boss replaces your OEM wheels with a two-part system featuring replaceable gripper bands—just rip out worn bands and push in new ones.

No machine stripping. No specialist charges. No days or weeks of waiting. Change bands between jobs and get back to production immediately.

Gripper Boss restoring gripper performance

OEM Gripper Wheels Are a Maintenance Disaster

The Fatal Flaw of OEM Grippers

OEM gripper wheels bond metal + rubber together permanently. When the rubber wears down—and it always does—you're stuck with two terrible options:

Option 1: Send wheels for re-gripping

- 1.Strip the entire machine to remove wheels

- 2.Send wheels to specialist for rubber bonding

- 3.Wait days or weeks for return

- 4.Pay rush charges if you need them urgently

- 5.Reassemble and calibrate machine

Option 2: Buy new OEM wheels

Even more expensive—often hundreds of pounds per wheel. Plus OEM rubber quality is often poor, so you'll be replacing them again soon.

The Gripper Boss Solution

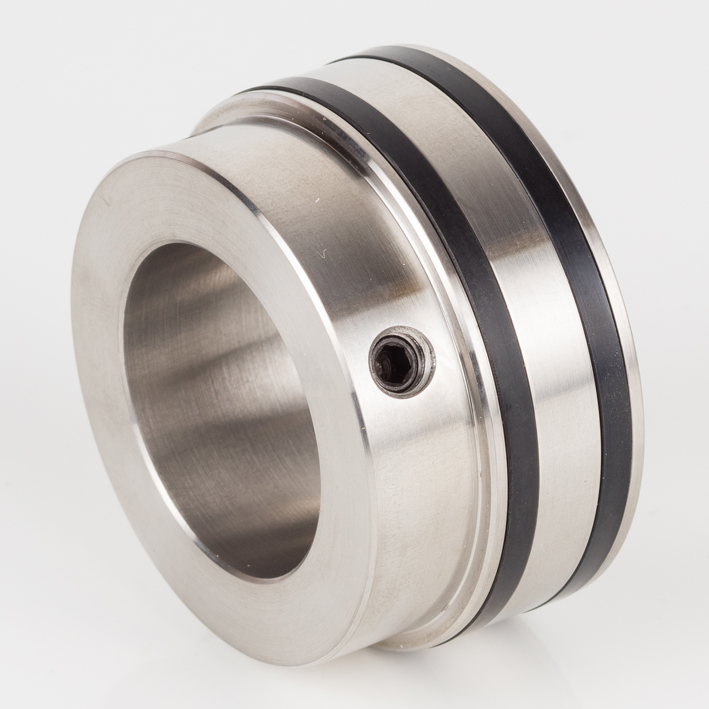

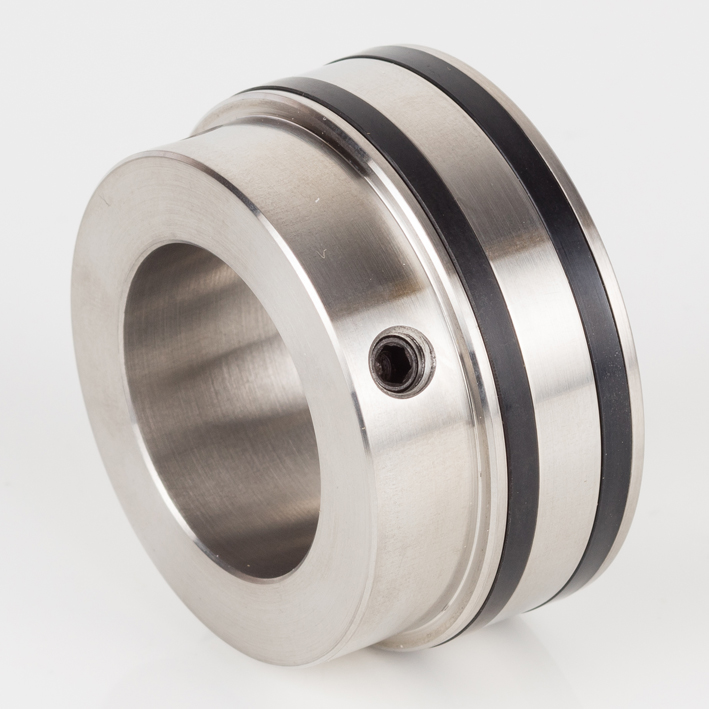

Replace OEM wheels once with Gripper Boss—then change bands in seconds forever. The two-part system uses a metal wheel with grooves that accept replaceable gripper bands.

The Two-Part System:

- ▸Top: Metal wheel with 2 grooves for replaceable gripper bands

- ▸Bottom: Full metal wheel (long-lasting, no wear parts)

- ✓Change bands in seconds—just rip out old, push in new

- ✓No machine stripping required

- ✓No sending wheels away

- ✓Superior grip to OEM rubber

- ✓Bands cost fraction of re-gripping

- ✓Stock bands on-site for instant changes

Visual Proof: Before & After

Without Gripper Boss

- • Degraded rubber surface

- • Poor grip causing slips

- • Annual regripping needed

- • Ongoing costs forever

With Gripper Boss

- • Permanent polymer grip

- • Consistent performance

- • Zero maintenance needed

- • One-time investment

Change Gripper Bands in 5 Simple Steps

Identify Worn Gripper Bands

When you notice grip quality declining or sheets slipping, it's time to change bands. Takes seconds to assess.

Pull/Rip Out Old Bands

Simply pull the worn bands out of the wheel grooves. No tools, no disassembly, no machine stripping. They rip out easily when worn.

Warm New Bands Slightly (Optional)

For easier insertion, warm bands slightly in your hands or with warm water. Makes them more pliable for snapping into grooves.

Push New Bands Into Grooves

Press new bands into the wheel grooves until fully seated. The bands snap into place securely—no adhesive, no specialist equipment.

Resume Production Immediately

Check grip and resume production—total time: seconds. No recalibration, no specialist sign-off, no waiting.

Change bands between jobs. Zero production downtime.

Why Operations Choose Gripper Boss

Eliminate Downtime

No more waiting days or weeks for specialist re-gripping. Change bands in seconds between jobs. Zero production delays, zero rush charges, zero scheduling headaches.

Result: Continuous production, no unplanned stoppages

Slash Maintenance Costs

Gripper bands cost a fraction of specialist re-gripping or new OEM wheels. Stock bands on-site for predictable maintenance costs—no surprise invoices.

Result: 90%+ savings vs OEM re-gripping over 5 years

Superior Sheet Grip

Premium rubber compound delivers better grip than OEM rubber. More consistent sheet transport, fewer misfeeds, improved registration—especially critical with Technifold finishing tools.

Result: Better quality, fewer jams, consistent performance

Additional Benefits:

The Business Case Writes Itself

5-Year Total Cost Comparison

| Scenario | OEM Approach | Gripper Boss |

|---|---|---|

| Initial Cost | Lower | Moderate |

| First Re-grip | £200-500 (send away) | £30-60 (bands only) |

| Downtime | Days/weeks | Seconds |

| Rush Charges | Often required | Never needed |

| Ongoing Cost (Years 2-5) | Unpredictable | Low, predictable |

| Total 5-Year Cost | HIGH | MUCH LOWER |

Hidden OEM Costs:

- •Lost production time while waiting for wheels

- •Rush shipping charges for urgent returns

- •Operator time stripping/reassembling machine

- •Missed deadlines and customer complaints

Works on Your Equipment

Folders

Compatible with most popular folder brands and models.

Perfect Binders

Upgrade gripper systems on binding equipment for consistent cover feeding.

Saddle Stitchers

Maintain consistent grip throughout high-speed stitching operations.

Stop Sending Wheels Away for Re-Gripping

See how Gripper Boss eliminates downtime and slashes maintenance costs. Change bands in seconds—not days.

3-month money-back guarantee • Stock gripper bands on-site for instant changes