Tri-Creaser

Totally Eliminates Fiber Cracking

The revolutionary rotary creasing solution that completely eliminates fiber cracking on all popular types of folding machines.

The resilient rubber compound penetrates the area prone to cracking with gentle rotary action—manipulating and stretching the fibres instead of damaging them like common steel scoring methods. Results equal to letterpress quality.

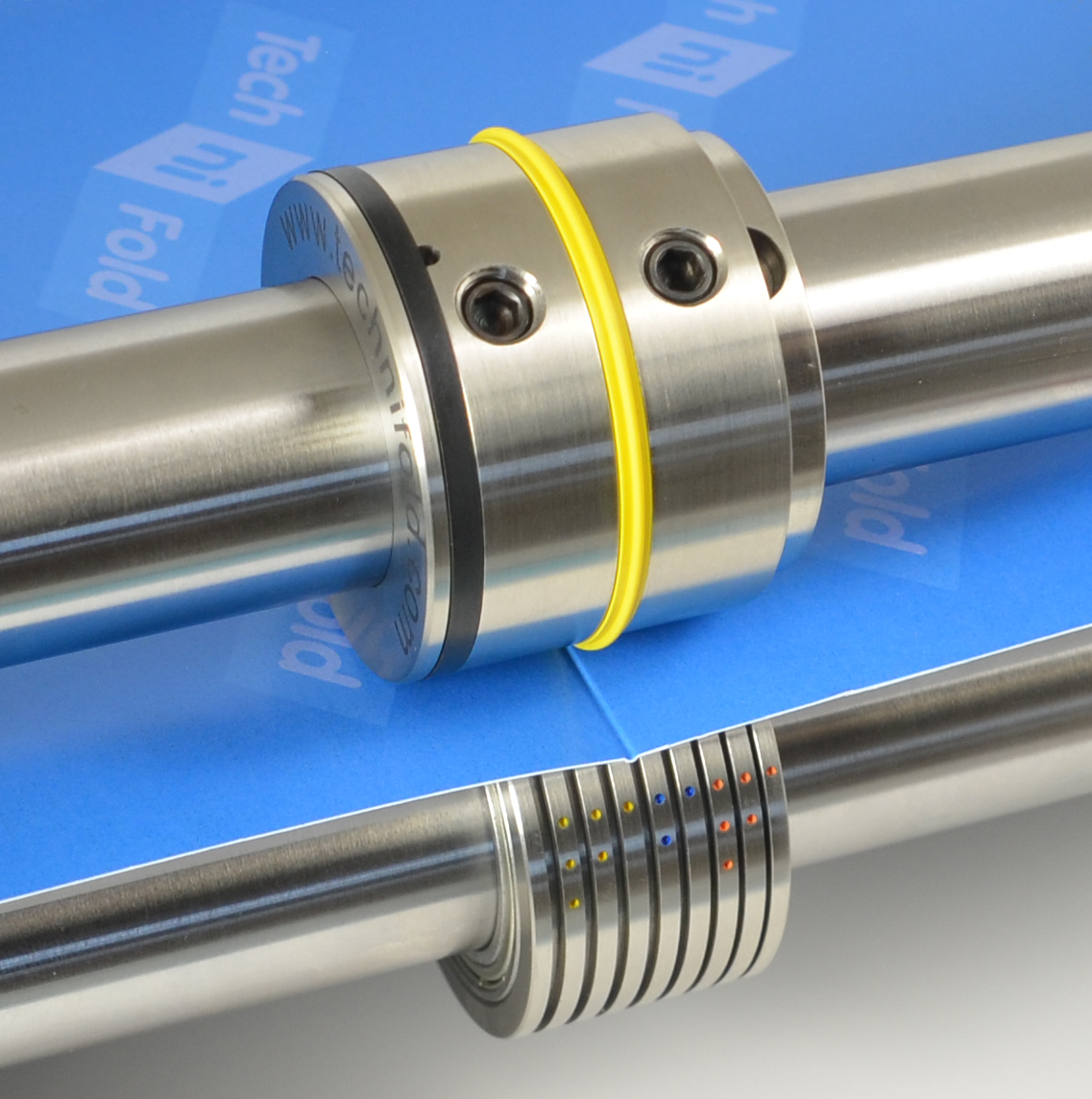

Tri-Creaser Fast-Fit creating letterpress-quality creases inline

You're Leaving Money on the Table Every Single Day

The customer wants the job in a hurry. You rush it through in record time. Perfect colors, tight registration. Then you fold it... and the material cracks along the spine.

You promised the job today. Now what?

Your OEM scoring tools are critically flawed.

They haven't evolved since 1850. They use a V-shaped steel blade that pushes fibres from the inside, causing spine damage. When used for creasing single cover stock, the steel is too harsh and destroys the fibres.

The Tri-Creaser works the opposite way—gently stretching the fibres from the outside, resulting in a smooth non-cracked spine and a perfect inside ridge.

The Cost of Traditional Scoring

- ✕Jobs crack on the fold—forcing expensive reprints

- ✕Send jobs to cylinder (if you have one)—or outsource and wait

- ✕30+ minutes per setup adjusting crease settings

- ✕Turning down premium work (laminated, UV, heavy stocks)

- ✕Losing jobs to competitors with better gear

£10,000 - £30,000

Annual waste reported by most printing companies

The Tri-Creaser Method

✕Traditional Scoring

- •V-shaped steel blade concentrates pressure

- •Crushes and destroys paper fibers

- •Shallow penetration = weak crease

- •Toner flaking on digital stocks

- •Technology unchanged since 1850

✓Tri-Creaser Method

- •U-shaped rubber rib spreads pressure

- •Compresses fibers without breaking them

- •Penetrates 3x deeper without damage

- •Rubber is "digital friendly" - no flaking

- •Patented technology, proven worldwide

Graham Harris's Discovery

Founder Graham Harris tested the 5 leading scoring devices worldwide before inventing Tri-Creaser. The breakthrough: crease on the TOP (outside) so the bulge is visible on the INSIDE after folding. This "reverse crease" method matched the proven Heidelberg Cylinder letterpress technique—achieving quality that rotary scoring was thought impossible to deliver.

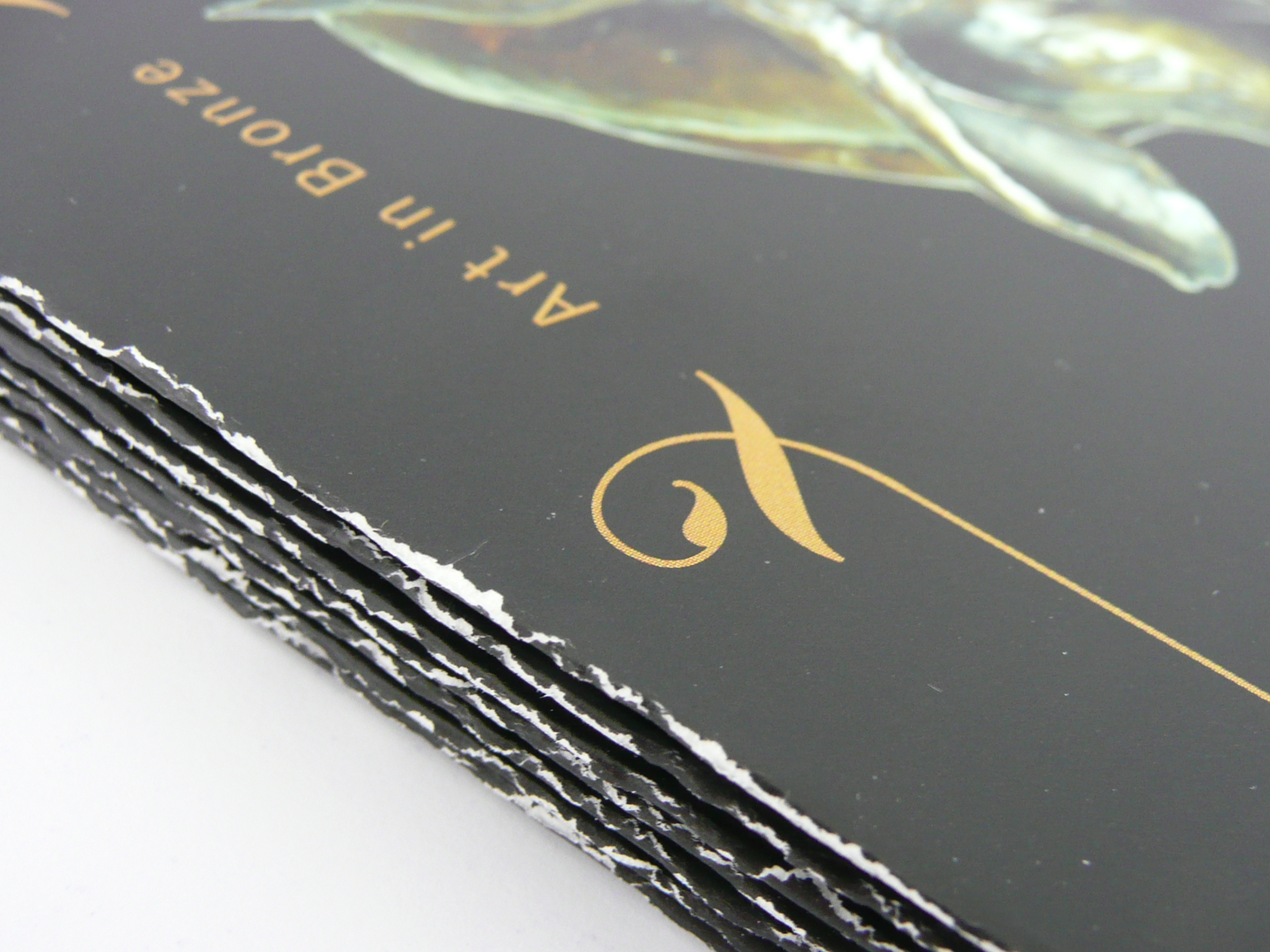

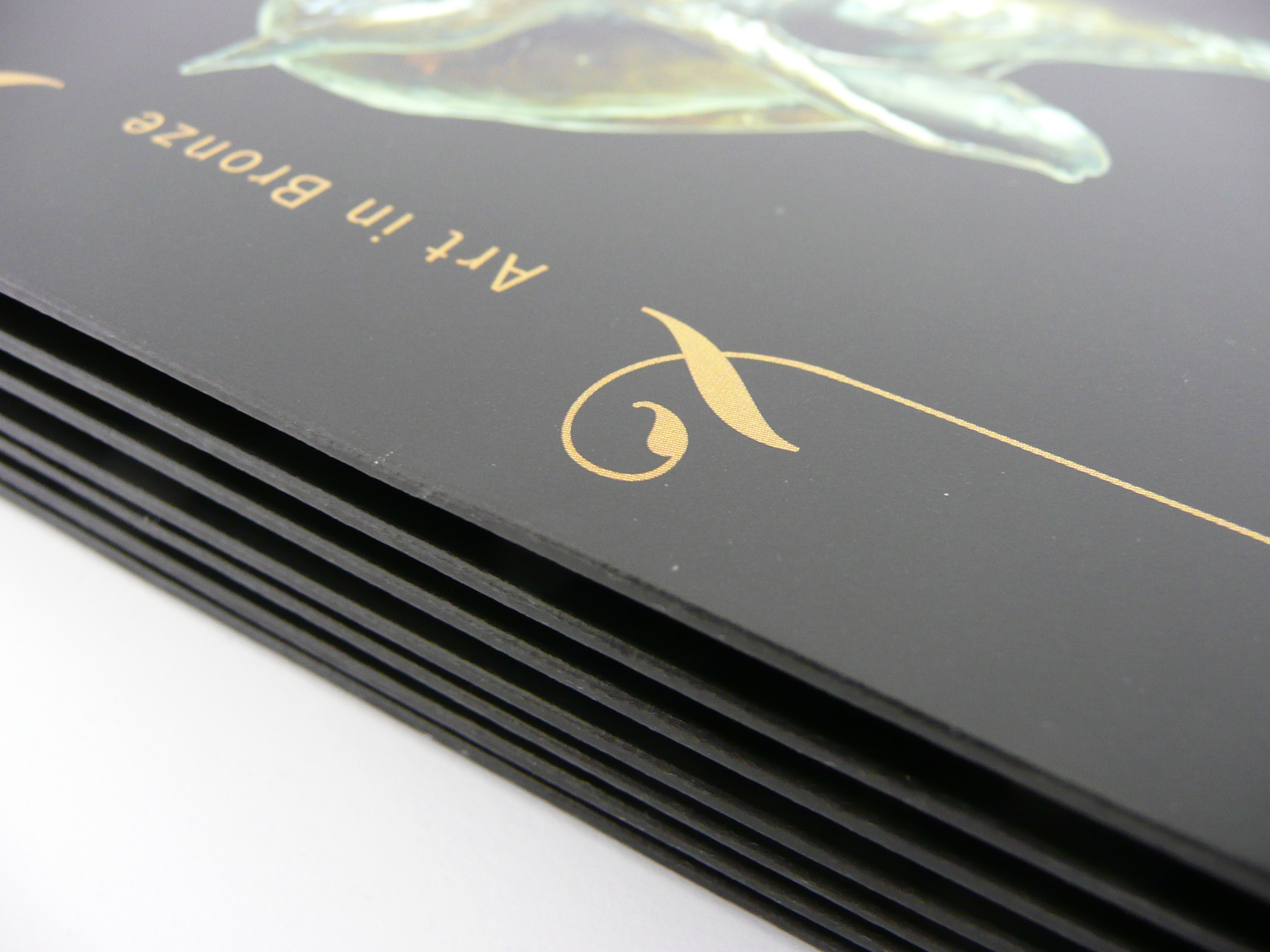

See the Difference: Metal Scoring vs. Tri-Creaser

Real results from actual production runs

Visible fiber cracking and surface damage along the fold line. This is the inevitable result of V-shaped steel blades crushing paper fibers.

Zero fiber cracking. Clean, professional fold that maintains coating integrity. The rubber creasing rib gently stretches fibers instead of breaking them.

See It In Action

Watch how the Tri-Creaser Fast-Fit installs in seconds and delivers letterpress-quality creases at full production speed.

- ✓Color-coded setup system

- ✓No machine modifications required

- ✓Change settings in seconds

Proven Performance. Globally Validated.

"The quality of this creasing is comparable with that produced in letterpress printing"

The Only Rotary Device That Totally Eliminates Fiber Cracking

- ✓Tested against the top scoring systems worldwide and outperformed them all significantly in ease of setup, efficiency, versatility and finished quality

- ✓Outsells competitors 20-1 in the global market

- ✓Heidelberg purchased 3,000+ units for OEM integration

- ✓Supplied to folding machine manufacturers GUK, MB, and other global leaders

Fast-Fit Split Creasing Ribs

Change from one crease setting to another instantly—never remove the device from your machine again

Light to medium stocks, standard digital output

Medium to heavy stocks, coated papers

Heavy stocks, board, laminated materials

Why Fast-Fit Saves You Time and Money

- ✓Split creasing rib technology—change settings without removing exit shafts from machine

- ✓Minutes to setup, seconds to change from one crease setting to another

- ✓Works like magic on difficult toner-based digital output

- ✓Works just as well when creasing against the grain as with it

- ✓No speed limitations—works as fast as your folding machine can run

- ✓Pays for itself within 1-3 job runs

Tri-Creaser Advance

Two-way creasing that tackles inside-fold toner flaking on particularly difficult digital stocks

The Inside-Fold Toner Flaking Problem

With changing paper manufacturing processes and paper quality standards, "inside-fold toner flaking" is a growing problem regardless of what creasing technology is applied.

The Tri-Creaser Advance is the world's first folding machine solution designed to prevent fiber-cracking on the fold AND tackle inside-fold toner flaking at the same time.

How Advance Works

- 1.Two-way creasing application using interlocking male and female components

- 2.U-shaped crease formed first, then main fold is placed on top of it

- 3.Areas prone to toner flaking are ironed out using specially profiled female ring

- 4.Simple color-coding maintained—still uses orange, blue, yellow system

Available as Complete System or Upgrade

Tri-Creaser Advance Complete: For first-time users looking to introduce unbeatable creasing power to your folding machine. Contains all components needed to produce better defined creasing.

Tri-Creaser Advance Upgrade: For existing Tri-Creaser Easy-Fit or Fast-Fit users. Use your existing male components in combination with the Tri-Creaser Advance Female.

ROI That Speaks for Itself

"We purchased the Tri-Creaser Easy Fit in August and it has only taken us four weeks to recover our investment. Now that we know the system works so well we estimate that it may save us £20,000 in the next 12 months."

"The savings we made by not having to send out for scoring paid for our Tri-creaser on the first job!"

"We had a difficult job with bleeds on both sides and the grain going the wrong way, the outside looked great but the inside was cracking. We just got a new Tri-Creaser Advance in and after a little trial and error, both sides looked great. We only had 1, the next day I ordered 2 more. We delivered that job on time and it saved us from getting a letterpress score and missing a deadline."

"We have used the Tech-ni-Fold Tri-Creaser in-line on our folders for a number of years, it is a very quick system to make ready and the results are equal to a cylinder crease. Because we can crease in-line, we are able to achieve speeds of up to 30k sheets per hour on our Heidelberg Stahl folders, eliminating all cracking across a multitude of stock types."

"We run a 300gsm silk job for a perfume brand. The job is laminated on the outside but not on the inside. The Tri-Creaser Advance gives a beautiful square crease result on the inside of the fold by producing a deeper impression. The Tri-Creaser Advance is an improvement even on previous versions."

Ready To Eliminate Cracking Forever?

Join 40,000+ installations worldwide. Most companies see full payback within 1-3 job runs.