Micro-Perforator

Stop Outsourcing. Start Producing Flatbed-Quality Perfs Inline.

Are you fed up with broken perf blades, outsourcing delays, and sheets that jam laser printers? The Micro-Perforator produces nearly invisible micro-perfs up to 72 teeth per inch—inline on your folder.

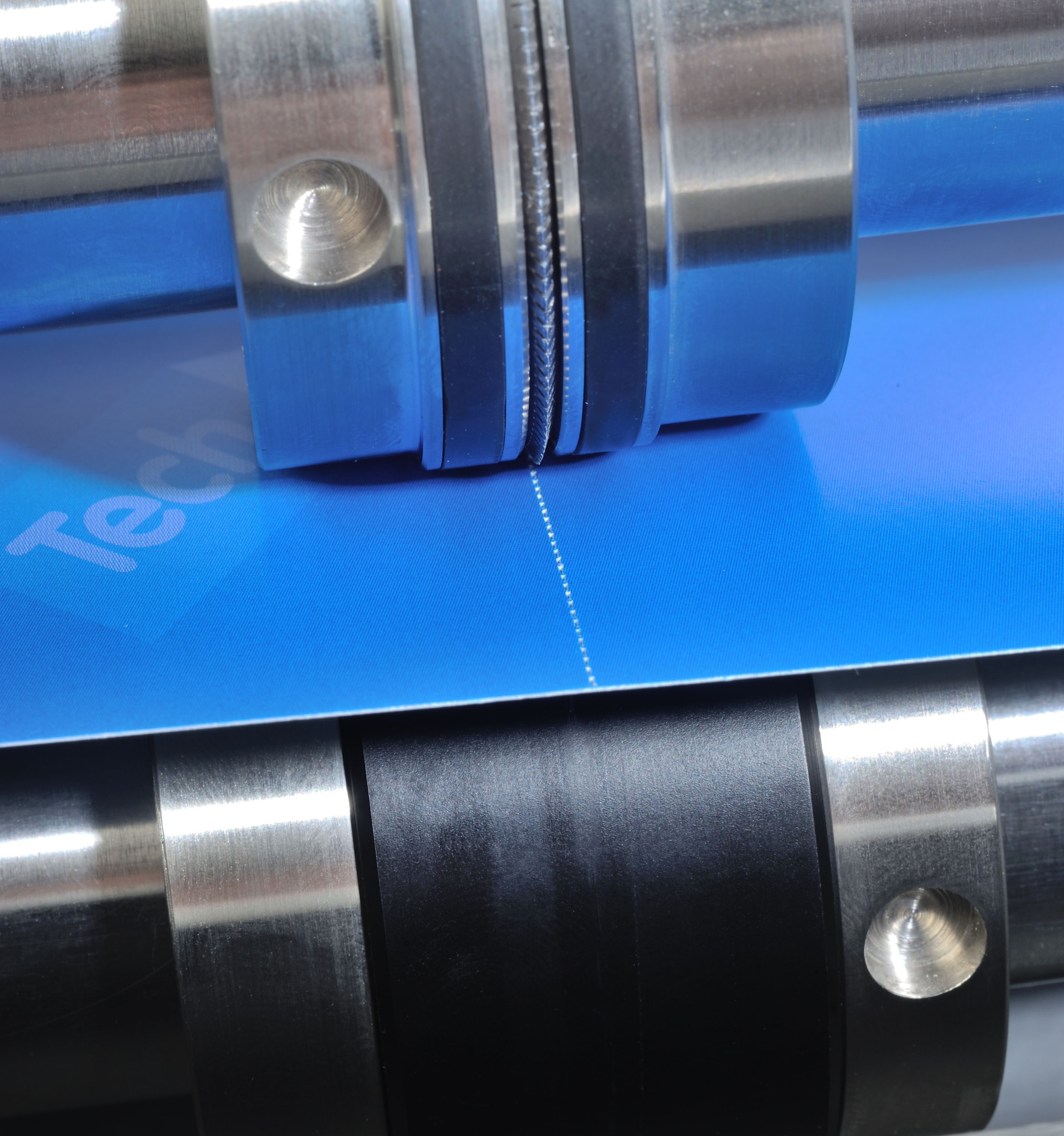

Kiss-cut technology. Break-resistant double-bevel blades. Cuts against soft nylon, not destructive steel. Sheets lie perfectly flat and run through any digital device without jamming.

Micro-Perforator creating precision perforations

Your Folder's Perf System Is Destroying Your Jobs

Does This Look Familiar?

Broken perf blades. Burred edges. Constant replacement orders. Your standard folding machine perf system uses 12 TPI blades that run metal-against-metal—a recipe for disaster.

Why Standard Perf Systems Fail:

- 1.Metal-on-metal destruction: Blade runs against steel anvil. Something always breaks when you least want it to.

- 2.Sheet distortion in 3 directions: Downward as blade enters, upward as it exits, horizontal as it pushes paper away from counter knife.

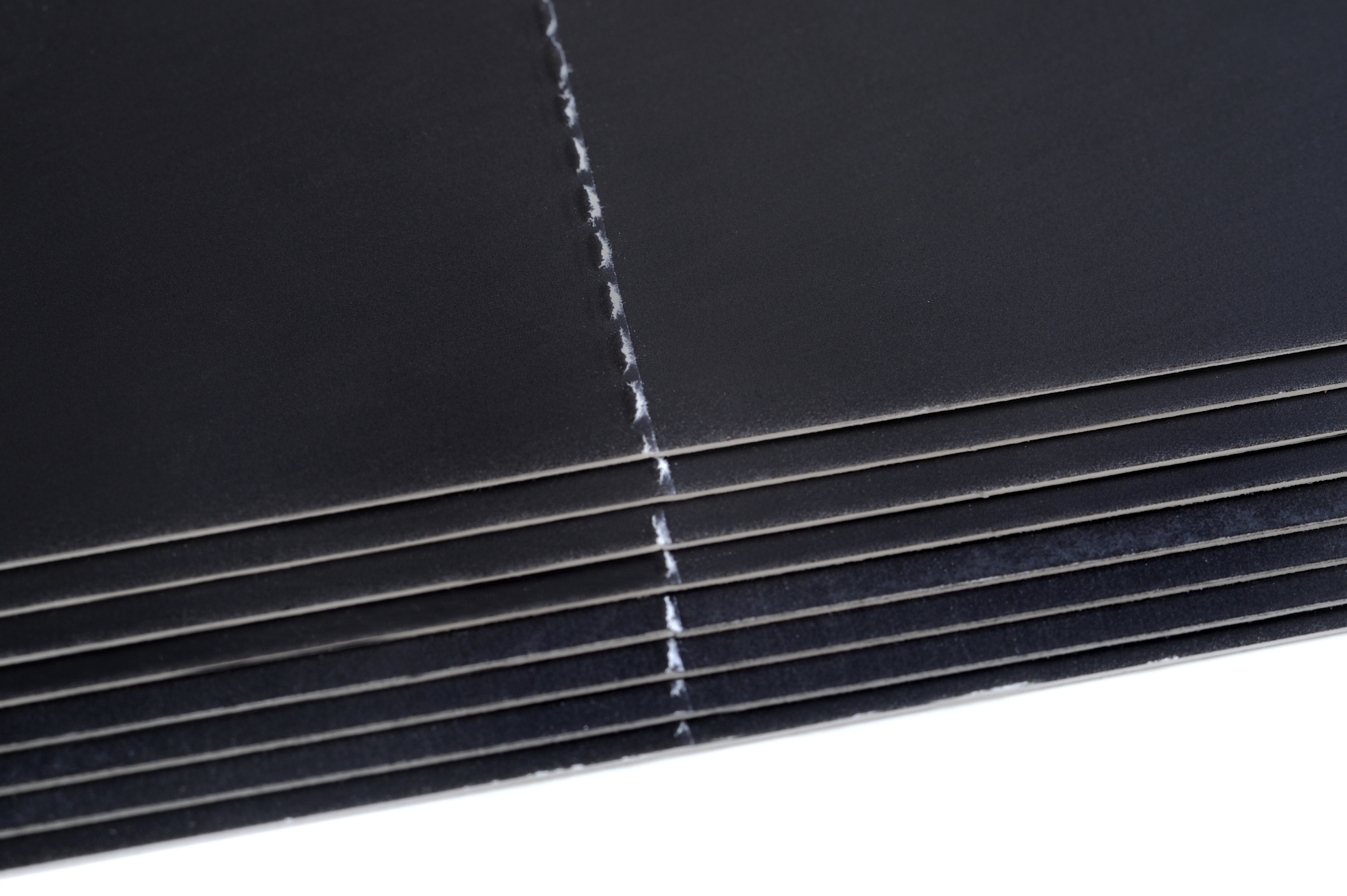

- 3.Creates a jagged, unsightly "torn" look that customers reject. Paper dust and ridges jam laser printers.

The ridge formed by conventional perforating builds up to create an oval-shaped stack that makes guillotining troublesome and won't lie flat.

The Cost of Poor Perforation

- ✕Outsourcing delays: Gather sheets, send to press perf or die cutter, wait for return

- ✕Smashed press blankets: Thousands of pounds wasted when perf rules damage blankets

- ✕Laser printer jams: Sheets with ridges won't run through digital devices for variable data

- ✕Turned-away work: Jobs you can't take because you don't trust your perf system

- ✕Constant blade replacements: Burred edges and broken teeth add up month after month

It doesn't have to be this way.

What if there was a rotary solution that matched flatbed letterpress quality?

Kiss-Cut Technology That Changes Everything

The Tech-ni-Fold Micro-Perforator

Created after extensive market research, the Micro-Perforator is the only rotary solution that replicates proven flatbed cylinder results. It was designed using new technology that adds strength and longevity, so it outlasts conventional methods many times over.

Unlike conventional perfs, the Micro-Perforator is designed to kiss-cut the sheet. The narrow profile blade cuts through only to the bottom of the sheet—not beyond—minimizing the knife area in actual contact with the sheet.

How It Works

- 1.Shock-absorbing cushion mount: The blade is mounted on a special cushion that delivers accurate, precise kiss-cuts the entire length of the sheet.

- 2.Cuts against soft nylon, not steel: This is the game-changer. Blade runs against a softer material, eliminating the metal-on-metal destruction.

- 3.Double bevel construction: Blades are break-resistant by design. Hard-wearing steel specially engineered to penetrate paper without damage.

- 4.Rubber grippers keep sheets stable: Two rubber grippers adjacent to the perf wheel maximize grip, prevent "tailing," and keep sheets perfectly flat.

The Results

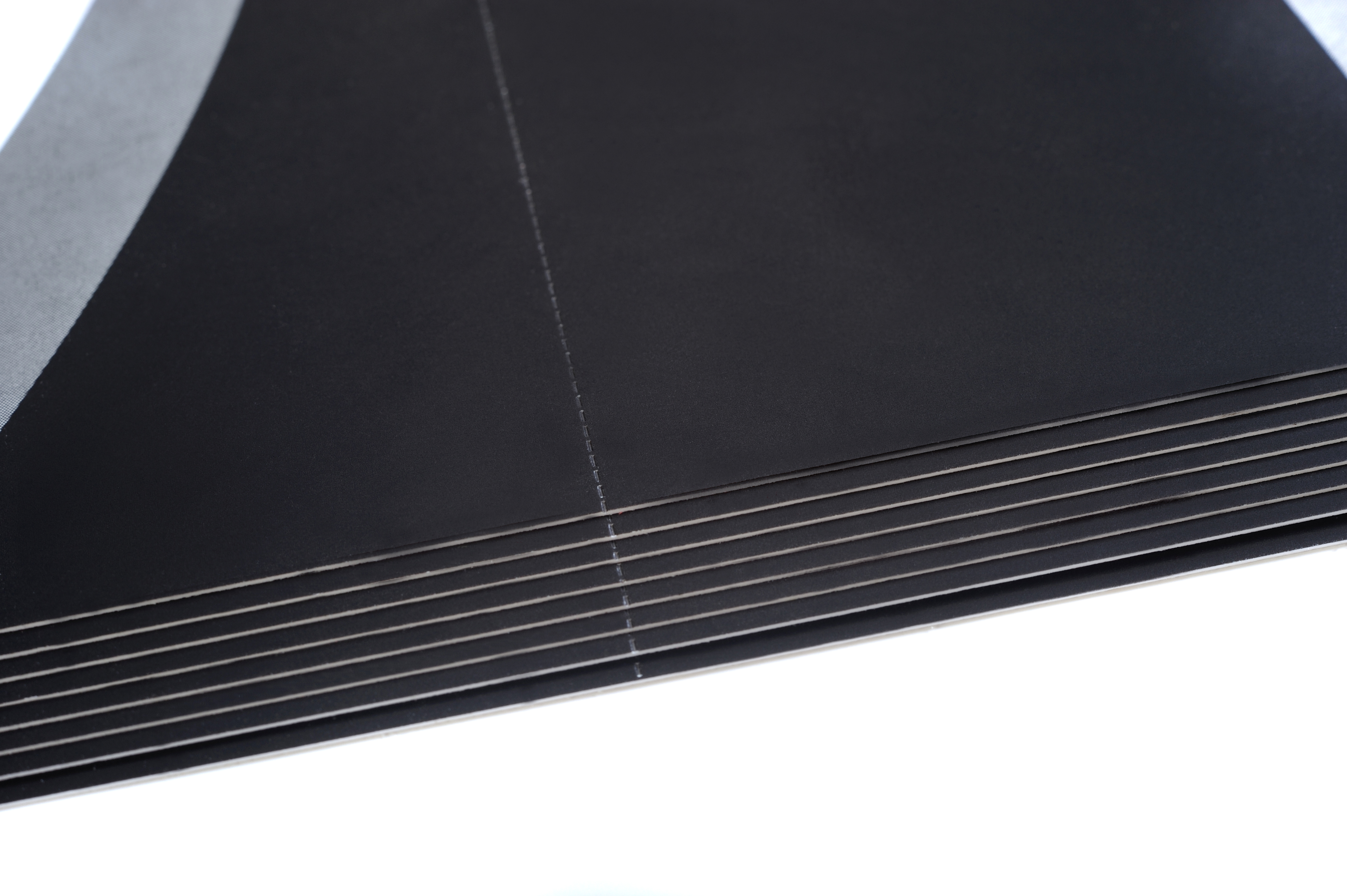

- ✓Cleaner, finer cut that permits sheets to lie perfectly flat

- ✓Nearly invisible perforations up to 72 teeth per inch

- ✓Perfect, straight-line micro perfs without the cost or headache

- ✓Sheets run through laser printers and copiers without jamming

- ✓Flat stacks—no oval shape from ridge buildup

- ✓Blades last for millions of sheets without wear or broken teeth

Visual Proof: Before & After

Without Micro Perforator

- • Visible fibre "flags"

- • Uneven tear lines

- • Printer jam risk

- • Customer complaints

With Micro Perforator

- • Clean tear edge

- • No fibre residue

- • Laser-safe feeding

- • Zero complaints

Transform Your Perforation Capability

Eliminate Outsourcing

No more sending jobs to flatbed cylinders or die cutters. Produce letterpress-quality micro-perfs inline on your folder at full speed.

Save hours and days in turnaround time

Instant ROI

Recover your investment in just 2 jobs. Eliminate outsourcing costs, stop replacing broken blades, and save thousands on press blankets.

Phil Fredericks recovered cost on second job

Sell More Work

Take jobs you used to turn away. Produce sheets that run through laser printers for variable data applications. Offer perforation as a value-add service.

Free up your press and die cutter for profitable work

Additional Benefits:

Standard Package Includes Three Blade Options

Perfect for heavyweight materials where strength matters

The workhorse blade for most standard applications

Nearly invisible perforation for fine work

Additional Options Available

72 TPI: Ultra-fine, almost invisible perforation (available for most models on request)

12 TPI: Very heavy stock perforation for specialized applications

Works With All Major Folding Machines

Also compatible with: CreaseStream and DCM creasing machines. Contact us to confirm fitment for your specific model.

ROI in Just Two Jobs

"We have just completed our second job with the Micro-Perforator and have already recovered the cost we paid for it. Now we can complete work quicker with superior results than previously, and with a lot more control."

Stop Outsourcing. Start Producing Inline.

See how the Micro-Perforator eliminates broken blades, outsourcing delays, and laser printer jams.